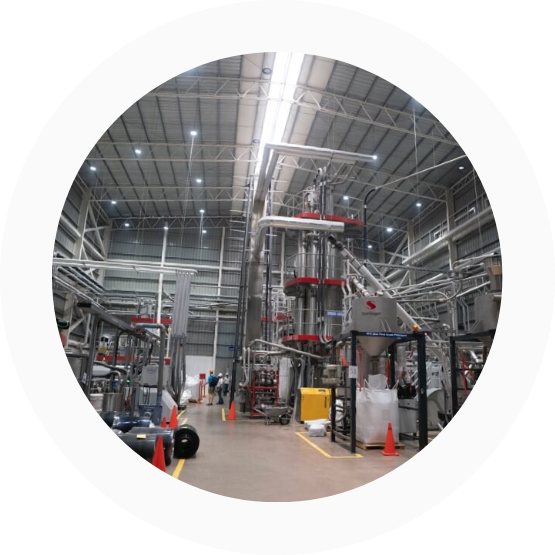

For the last several years we have invested heavily in the research and development of

sustainable materials. We also have production lines specifically set up to test the

feasibility of the materials for large scale manufacturing.

We strive to be leaders in the sustainable products movement. We are

acutely aware that what we do as manufacturers has a direct impact on

the environment, and that we have the power to make systemic change

a reality. We are making positive steps towards changing the way we work

and are actively researching materials and manufacturing methods

that can help make an impact.

For the last several years we have invested heavily in the research and development of

sustainable materials. We also have production lines specifically set up to test the

feasibility of the materials for large scale manufacturing.

In 2020 we initiated a program in China that uses post-industrial waste from fast food chains. Every year, millions of cups, plates, forks, and bottles are thrown into landfills. A lot of attention and press has been focused on Ocean Plastics. We feel that land-based waste is just as harmful to the environment and would like to do our part to solve this problem. We are now collecting this material, cleaning it, and re-processing it at our plant in Foshan, Guangdong province. Our goal is to use roughly 30% of up-cycled material in many of our product lines. We have passed all relevant global recycling standards and are FDA and LFGB compliant.

This is a recycled raw material that can substitute virgin plastics, help protect our oceans and planet, and contribute to the circular economy.

Ocean Bound Plastic refers to plastic waste that is at risk of ending up in the oceans. This means plastic that is located near waterways that may find its way through rivers and lakes. Risk areas are worldwide and are defined as being 200 kilometers from the coastline. The goal of using

this material is to create an integrated land-based collection system that converts Ocean Bound Plastic waste into recycled products.

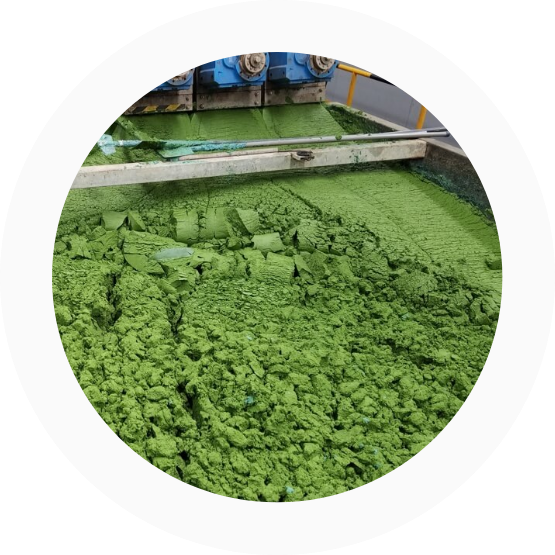

Rise in global temperatures, excess nutrient runoff, and human activities have led to devastating situations like massive algal blooms all around the world. Water pollution is an invisible problem made visible by rampant algae growth. We’ve partnered with a company that is determined to reverse the effects of water pollution by working with natural resources like algae to create sustainable materials, generate clean water, and maintain healthy ecosystems. As a result of this partnership, we now use Algae-based materials to produce sustainable products.

Stainless steel is the most recycled material on the planet, and we’re part of the reason why.

In 2020 we initiated a program to use certified stainless steel at our factories as a substitute for virgin material. Stainless steel is non-degradable, with little or no impact on performance after recycling. Recycling reduces energy consumption, overall carbon footprint, and the size of landfills. Additionally, it allows us to reduce costs in most cases while contributing to systemic change and the health of our planet.

© Velong Enterprises. All Rights Reserved